self-operated (after-valve) pressure control valve

| Model: | 30D01Y 30D01R |

| Place of Origin: | Zhejiang,China (Mainland) |

| Brand Name: | Tisun |

|

Ningbo Tisun Seals Industries Co., Ltd.

self-operated (after-valve) pressure control valve, China self-operated (after-valve) pressure control valve Manufacturer

|

| Model: | 30D01Y 30D01R |

| Place of Origin: | Zhejiang,China (Mainland) |

| Brand Name: | Tisun |

| Payment & Shipping Terms | Supply Capacity | ||

|---|---|---|---|

| Payment Terms: | L/C, T/T, WU | Packing: | wooden carton |

| Min. Order: | 1 pcs | Delivery Date: | 7 dyas |

| Means of Transport: | Ocean, Air, Land | ||

DN | DN15 20 25 32 40 50 65 80 100 125 200 250mm | |

PN | PN1.6 4 .0MPa | |

Flange standard | ANSIJISDIN GB JB(special standards can be offeredaccording to user requirements) | |

Body material | Cast iron (HT200), cast steel (ZG230-450), caststainless steel (ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2T i) | |

Plug material | Hard seal | Stainless steel (1Cr18Ni9Ti, 1Cr18Ni12Mo2Ti) |

Soft seal | Stainless steel embedded with rubber ring | |

Pressure balancing | Stainless steel bellows(DN15~125), balanced diaphragm (DN150~250) | |

Effective area (cm2) | 32 | 80 | 250 | 630 |

Pressure setting range | 0.8~1.6 0.3~1.2 | 0.1~0.6 0.05~0.3 | 0.015~0.15 0.01~0.07 | 0.005~0.035 |

Minimum differential pressure that ensures normal work of thepressure valve | ≥0.05 | ≥0.04 | ≥0.01 | ≥0.005 |

Allowable maximum differential pressure between the upper a nd lowerdiaphragm chambers | 2.0 | 1.25 | 0.4 | 0.15 |

Material | Diaphragm cover: galvanizedsteel sheet; Diaphragm: EPDM or FKM withfiber | |||

Control pipeline connection | Copper pipe or steel pipe Φ10X1(mm); Ferrule connection: R1/4" | |||

Set value error | ±8% | |

Allowable leakage (under stipulated testingconditions) | Hard seal | 4x0.01% valverated capacity |

Soft seal | DN15~50 DN65-DN625 DN150~250 | |

10 bubbles/ min 20 bubbles/min 40 bubbles/min | ||

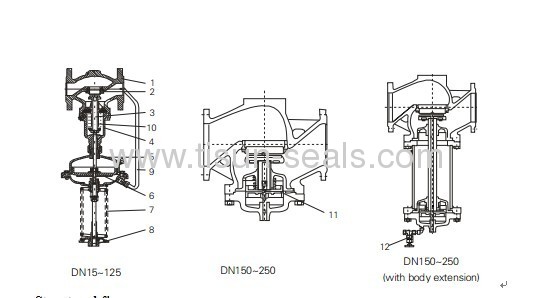

1Body | 2Seat | 3 Valve shaft | 4 Bonnet | 5 Diaphragm | 6 Diaphragm cover |

7Spring | 8 Adjusting nut | 9 Pressure pipe | 10 Bellows | 11 Balanceddiaphragm | 12Charging valve |

DN | 15~125mm | 150~250mm | |

seal type | Hard seal | ≤150℃ | ≤140℃ |

Cooling tank≤200℃ | Cooling tank and extension ≤200℃ | ||

Cooling tan k and heat sink ≤350℃ | Cooling tank and extension ≤300℃ | ||

Soft seal | ≤150℃ | ||

II. Dimensions and weight of actuator

Effective area (cm) | 32 | 80 | 250 | 630 |

R (mm) | 172 | 172 | 263 | 380 |

H (mm) | 435 | 430 | 470 | 520 |

Weight(Kg) | 7.5 | 7.5 | 13 | 28 |

Category: others